- Oil Pipeline

- Water Pipeline

- Gas Pipeline

- Boat and Mooring Accessories

- Metal for Decoration

- Transformer Components

- Heat Exchanger Pipe

- Air Conditioning Spare Parts & Accessories

- Boiler

- Kitchen and Bathroom Appliance

- Metal for Household Appliance

- Solar Power Appliance

- Elevator

- Roofing and Ceiling

- Cable

- Tank

- Packaging

- Machinery and Equipment Spare Parts & Accessories

- Mold

- Automobile Parts

- Rail and Crane Rail

- Hardware Fitting

- Abrasive

- Road Construction Equipment

- Electronic Components

- Construction and Decoration Materials

- Doors and Windows

- Refrigerators

Round Enameled Aluminum Wire For Compressor

Standard: GB IEC JIS NEMA

Certification: passed UL, SGS, ROHS, ISO9001

Others: can offer OEM service, customized colour and packaging

Among all of its high-tech magnet wire products ,SMC offers a complete range of round enameled wire with aluminum as the conductor.

We pride ourselves in excellent quality products with competitive pricing and prompt delivery.

Specifications of Round Enameled Aluminum Wire:

Size: 0.12mm-1.50mm

Class: 130 / 155 / 180 / 200 / 220

Coating material: polyurethane, polyester, polyesterimide, polyimide, nylon

Film coating thickness: based on the standards and requested by clients

Standard: GB IEC JIS NEMA

Certification: passed UL, SGS, ROHS, ISO9001

Others: can offer OEM service, customized colour and packaging

Facility of Round Enameled Aluminum Wire :

SMC has taken the lead in importing the Round Enameled Aluminum Wire production and

inspection equipment of the advanced international standards .

The annual output of the Round Enameled Aluminum Wire and other Enameled wire over 7,000 tons

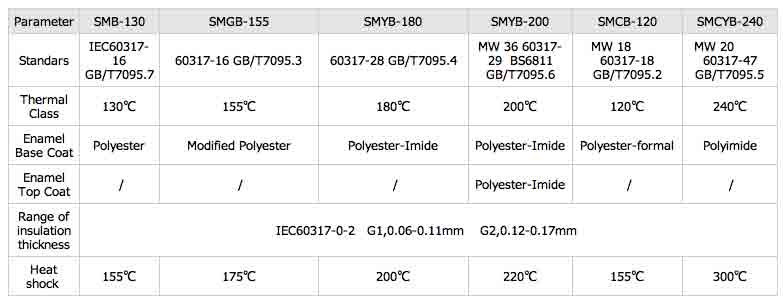

Parameter of Round Enameled Aluminum Wire:

Packaging of Round Enameled Aluminum Wire:

Shanghai Metal Corporation Products are packed and labeled according to the regulations and customer's requests.

Great care is taken to avoid any damage which might be caused during storage or transportation.

In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)SMC Standard

2)Customization

Applications of Round Enameled Aluminum Wire:

a)Small transformers, linear motors, relays, solenoids, small motors, clock coils, watch coils,

magnetic heads

b)Automotive sensors and coils as relais and ignition coils

c)Generators,dry-type or oil-immersed

d)Anti-explosion motor,air-conditioner compressor,washing machine

e)Military and space applications

Features of Round Enameled Aluminum Wire:

1) Excellent bending property

2) High flexibility of the enamel

3) Good resistance to abrasion

4) High mechanical property

5) Higher thermal property

6) Good resistance to refrigerant and freon

7) Suitable for windings that are subjected to constantly high temperature and mechanical stress

8) Good chemical resistance

9) Outstanding mechanical and chemical property

here

for

price

We will contact with you within 8 hours