- Oil Pipeline

- Water Pipeline

- Gas Pipeline

- Boat and Mooring Accessories

- Metal for Decoration

- Transformer Components

- Heat Exchanger Pipe

- Air Conditioning Spare Parts & Accessories

- Boiler

- Kitchen and Bathroom Appliance

- Metal for Household Appliance

- Solar Power Appliance

- Elevator

- Roofing and Ceiling

- Cable

- Tank

- Packaging

- Machinery and Equipment Spare Parts & Accessories

- Mold

- Automobile Parts

- Rail and Crane Rail

- Hardware Fitting

- Abrasive

- Road Construction Equipment

- Electronic Components

- Construction and Decoration Materials

- Doors and Windows

- Refrigerators

Hastelloy C-276

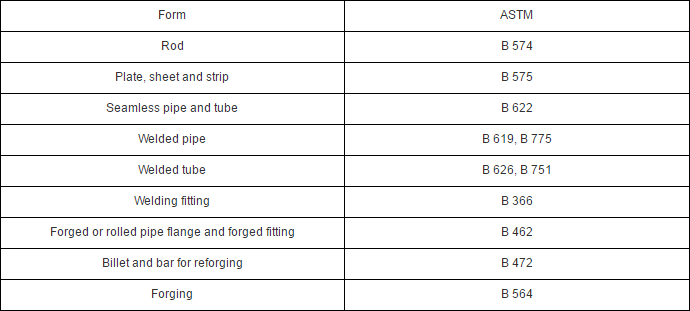

Standard: ASTM ASME

Certification: ISO 9001:2008

Color: Nickel Nature

Specification:

Equivalent designations: Hastelloy C-276, UNS N10276, NC17D, DIN W. Nr. 2.4819, NS334,00Cr16Ni60Mo16W4

Place of Origin: Shanghai, China (Mainland)Application: Chemical processing, waste treatment, pollution control, pulp and paper production, and marine engineering.

Product list:

Specification:

Wire: 0.01-10mmStrip: 0.05*5.0-5.0*250mm

Bar: φ4-50mm; Length 2000-5000mm

Pipe: φ6-273mm;δ1-30mm; Length 1000-8000mm

Sheet: δ0.8-36mm; Width 650-2000mm; Length 800-4500mm

Model Number: Hastelloy C-276

Brand Name: SMCShape: Forging

Standard: ASTM ASME

Certification: ISO 9001:2008

Color: Nickel Nature

Packing: Common sea freight wooden case package/ Also can be customized

Payment: L/C,T/T

Delivery: Usually sample lead time is 7 days after payment has been confirmed.

Hastelloy C-276 has excellent resistance to localized corrosion, stress corrosion cracking, and to both oxidizing and reducing media, thus making it suitable for a wide variety of chemical process environments, including ferric and cupric chlorides, hot contaminated media (organic and inorganic), formic and acetic acids, seawater and brine solutions. It is one of the few materials that withstands the corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide.

1. Produces process

Raw material→ Smelting→ Drawing→ Rolling→ Annealing→ Finished product→ Detection→ Packing→ Shipping

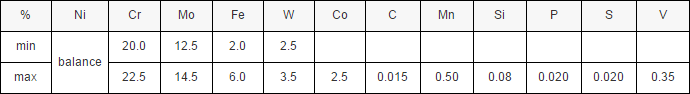

2. Chemical composition

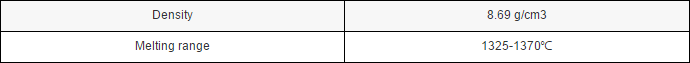

3. Physical properties

Characters:

Excellent corrosion resistance in reducing environments.

Exceptional resistance to strong solutions of oxidizing salts, such as ferric and cupric chlorides.

High nickel and molybdenum contents providing good corrosion resistance in reducing environments.

Low carbon content which minimizes grain-boundary carbide precipitation during welding to maintain resistance to corrosion in heat-affected zones of welded joints.

Resistance to localized corrosion such as pitting and stress-corrosion cracking.

One of few materials to withstand the corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide.

Application:

Pollution control stack liners, ducts, dampers, scrubbers, stack-gas reheaters, fans and fan housings.

Flue gas desulfurization systems.

Chemical processing components like heat exchangers, reaction vessels, evaporators, and transfer piping.

Sour gas wells.

Pulp and paper production.

Waste treatment.

Pharmaceutical and food processing equipment.

here

for

price

We will contact with you within 8 hours