- Oil Pipeline

- Water Pipeline

- Gas Pipeline

- Boat and Mooring Accessories

- Metal for Decoration

- Transformer Components

- Heat Exchanger Pipe

- Air Conditioning Spare Parts & Accessories

- Boiler

- Kitchen and Bathroom Appliance

- Metal for Household Appliance

- Solar Power Appliance

- Elevator

- Roofing and Ceiling

- Cable

- Tank

- Packaging

- Machinery and Equipment Spare Parts & Accessories

- Mold

- Automobile Parts

- Rail and Crane Rail

- Hardware Fitting

- Abrasive

- Road Construction Equipment

- Electronic Components

- Construction and Decoration Materials

- Doors and Windows

- Refrigerators

铜包铝管(射频电缆导体管)

Grade: C11000 copper , 3003 aluminum

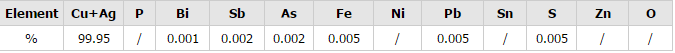

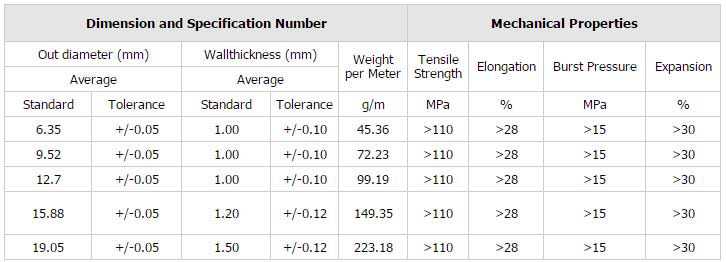

Outside Diameter: 6.35mm-19.05mm

Wall Thickness: 0.5mm-1.20mm

Specifications of Copper Clad Aluminum Tube:

1)Grade:C11000 copper , 3003 aluminum

2)Outside Diameter: 6.35mm-19.05mm

3)Wall Thickness: 0.5mm-1.20mm

4)Tensile: 150-190MPa

5)Elongation: 35%-40%

6)Expanding: >40%

Features of Copper Clad Aluminum Tube:

1) Good heat-transmit performance

2) Heat conduction

3) Good elongation

4) Being extruded and processed well

5) Good corrosion-resistance

6) Climate-hardiness

7) Excellent heat- sinking capability

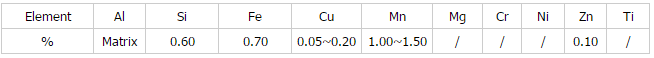

Chemical Composition:

Alloy Number: 3003 Aluminum

Copper: T2 (C1100 in JIS;C11000 in ASTM)

Nominal Datum :

Specific Gravity:4.3g/cm³

Bright Tubes

*Shadowed area show the normal products we can make.

Packaging of Copper Clad Aluminum Tube:

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)Shanghai Metal Standard

2)Customization

Applications of Copper Clad Aluminum Tube:

>Radio Frequency Cable

>Connection tube

>Fittings

>Refrigeration tube

>Coaxial Cable

>Inner conductor of RF cable

etc.

The outer layer of CCA tube is T2 or C1100 copper, and the inner layer is antirust 3003 Aluminum Alloy, and the middle layer is the Metallurgy integrated Layer of copper and Aluminum.

Thermal Conductivity for Copper is about 380 w/m*c, compared to 237 w/m*c for Aluminum, which is only approximately 60% of Copper thermal Conductivity.

As aluminum is the material for inner tube, it is better materials to preserve heat than copper. The weight ratio between copper and aluminum is approximately 55:45, and volume ratio between copper and aluminum is approximately 25:75, with density of 4.3. Compared to copper tubes, it can save up to 45% of the cost. The tensile strength is between 150 and 190MPa, elongation is between 35% and 40%.

Pressure resistance level is above 15Mpa. With unique two-layer structure design it has very strong pressure resistance, making it reliable and safer to use.

here

for

price

We will contact with you within 8 hours

.jpg)