- Oil Pipeline

- Water Pipeline

- Gas Pipeline

- Boat and Mooring Accessories

- Metal for Decoration

- Transformer Components

- Heat Exchanger Pipe

- Air Conditioning Spare Parts & Accessories

- Boiler

- Kitchen and Bathroom Appliance

- Metal for Household Appliance

- Solar Power Appliance

- Elevator

- Roofing and Ceiling

- Cable

- Tank

- Packaging

- Machinery and Equipment Spare Parts & Accessories

- Mold

- Automobile Parts

- Rail and Crane Rail

- Hardware Fitting

- Abrasive

- Road Construction Equipment

- Electronic Components

- Construction and Decoration Materials

- Doors and Windows

- Refrigerators

不锈钢螺旋管

Standard: ASTM A554, JIS G3446 ,etc

Grade: 201, 202, 301, 304, 304L, 316, 316L, etc

Wall thickness: 0.25mm-3.0mm or custom

Specifications of Stainless Steel Spiral Pipes/Tubes:

1. Standard: ASTM A554, JIS G3446, etc

2. Grade: 201, 202, 301, 304, 304L, 316, 316L, etc

3. Outer diameter (mm): 9.5, 12.7, 16, 17, 18, 19, 20, 22, 23, 25, 28, 32, 36, 38, 47, 51, 60, 63, 73, 76, 89, 102, 114, 133, 141, 159, 219

4. Wall thickness: 0.25mm to 3.0mm

5. Tolerance:

A: Outer diameter: +/-0.15mm

B: Thickness: +/-10%

C: Length: +/-4.8mm - 0mm

6. Surface: Polish

7. Application: Structural, decoration (fencing, railing, balcony balustrades, antitheft doors/ windows, gate fittings, staircases, furniture fittings, sanitary wares fittings, kitchen wares fittings, mechanical fittings, tripod for camera, etc)

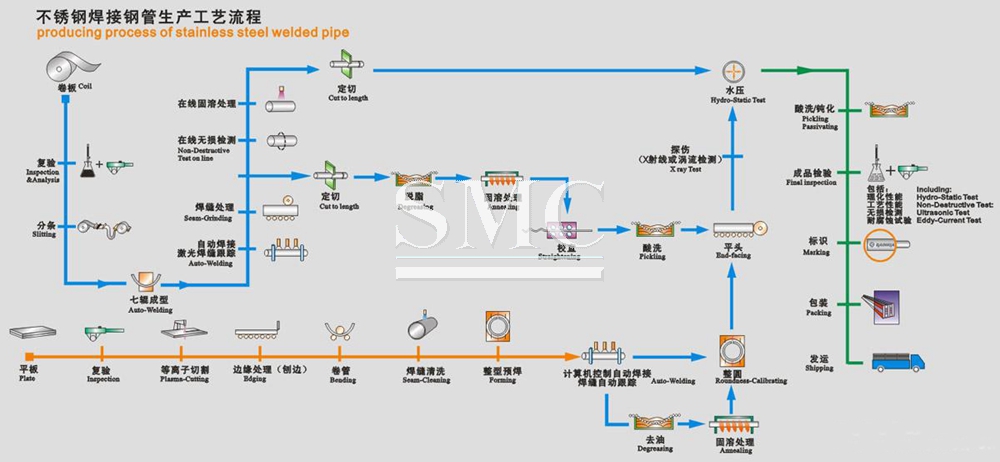

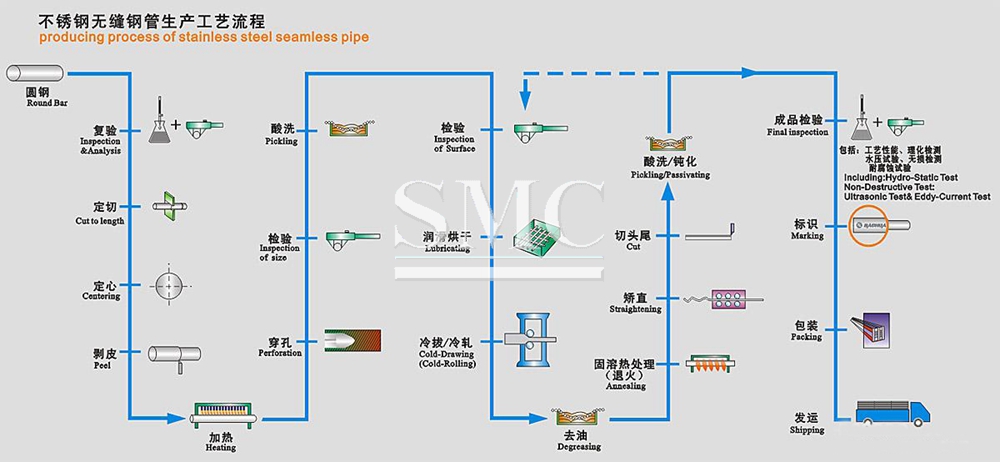

Production line

Manufacturing Process of Stainless Steel Pipes/Tubes:

The process commences with the formation of welded mother tube on the tube mill from imported and tested prime quality stainless steel strips. The latest TIG multi electrode welding technique is employed for superior weld quality and 100% Fusion, with argon purging, No filler metal added.

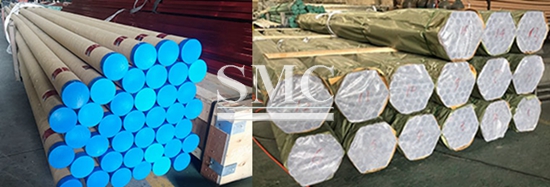

Packaging of Stainless Steel Spiral Tubes/Pipes:

Please don’t worry that our products are packed, stored, transported according to the international regulation. We do care about the quality of our products; even some little details are paid attention to.

We wrap the stainless steel products with anti-rust paper and steel rings to prevent damage. Identification labels are tagged according to standard specification or customer's instructions. Special packing is available as per customer's requirement.

Plus, our storage racks are made of wood. Other kinds of metals are settled in other places, far from the stainless steel. Any unwanted chemical reaction can be prevented.

Application of Stainless Steel Spiral Pipe/Tube:

The versatility of Spiral duct has lead to its use in a wide range of applications:

Spiral duct can now be found in numerous commercial applications including:

• Restaurants

• Churches

• Sports facilities

• Community centers

• Clinics and hospitals

• Schools and universities

• Retail stores and malls

• Community and entertainment facilities

• Office buildings and warehouses

• And many more

Spiral Pipe is used extensively in industrial applications:

• Removal of chemical fumes and other environmental toxins

• Removal of dust and other airborne particulates

• Removal of manufacturing byproducts such as sawdust and wood shavings

• Bulk material handling such as the loading of grain trucks and hoppers.

FAQ

Q: Can you do polished finish for the tubes/pipes?

A: Yes, for welded tubes/pipes, we can do mirror polishing, 600# polishing, 500# polishing, 320# polishing, 240# polishing and so on, brushed finish is also available. For seamless tubes/pipes, normally the surface is pickled finish, while brushed finish is also doable.

Q: What’s your standard package?

A: Our standard package is waterproof plastic bags with wraps. For advanced packing, we can provide round paper tube for each tube, and wooden/metal case for exterior packing.

Q: Where’s your main market?

A: South America, Mid-east, South-east Asia, Europe and so on.

Q: Do you also have the accessories for the tubes?

A: Yes we can provide the accessories too.

Q: What length is your standard length? Can I have the tubes/pipes cut into the length I want?

A: Our standard length is 3meter, 4meter, 5meter, 6meter. If you length is less than 3meter, we will have to run an additional processing for cutting which will bring some more costs. The minimum length is 500mm. For seamless tubes, we can make maximum to 12, 13meters.

here

for

price

We will contact with you within 8 hours