- Oil Pipeline

- Water Pipeline

- Gas Pipeline

- Boat and Mooring Accessories

- Metal for Decoration

- Transformer Components

- Heat Exchanger Pipe

- Air Conditioning Spare Parts & Accessories

- Boiler

- Kitchen and Bathroom Appliance

- Metal for Household Appliance

- Solar Power Appliance

- Elevator

- Roofing and Ceiling

- Cable

- Tank

- Packaging

- Machinery and Equipment Spare Parts & Accessories

- Mold

- Automobile Parts

- Rail and Crane Rail

- Hardware Fitting

- Abrasive

- Road Construction Equipment

- Electronic Components

- Construction and Decoration Materials

- Doors and Windows

- Refrigerators

Seamless Steel Pipe for Oil Drill Pipe

Standard: DIN, ASTM, API, JIS, GB

Wall Thickness: 2.11mm~300mm

Outer Diameter: from 21.3mm~1420mm

We specialize in the manufacture of hot rolled and cold drawn seamless steel pipe.

The factory presently has 205T, 150T, 60T and 40T pull out machine in the unit,

LD1005 rolled precision rolling mills, LD 852 rolled annular rings reduce the diameter mill train.

We accept customization, and offer the heat treatment service. Please send us your need.

Drill pipe, is hollow, thin-walled, steel or aluminium alloy piping that is used on drilling rigs.

It is hollow to allow drilling fluid to be pumped down the hole through the bit and back up the annulus.

It comes in a variety of sizes, strengths, and wall thicknesses,

but is typically 27 to 32 feet in length (Range 2). Longer lengths, up to 45 feet, exist (Range 3).

Specification of Seamless steel pipe:

1) Standard: DIN, ASTM, API, JIS, GB

2) Wall Thickness: 2.11mm~300mm

3) Outer Diameter: from 21.3mm~1420mm

4) Grade:10#, 20#, 45#, Q345, ST35.8, ST37, ST42, ST45, ST52,

API 5L /GR.B-X60, API 5CT /J55 K55 N80, A53, A106, A192, A179, A210, and etc.

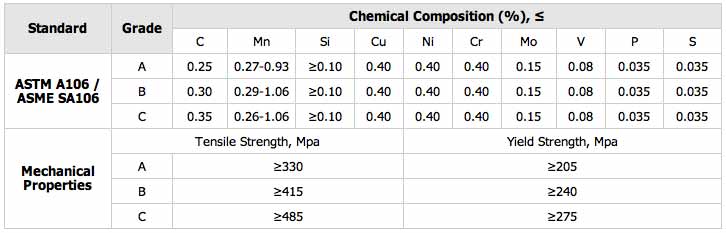

ASTM A106 Seamless Steel Pipe

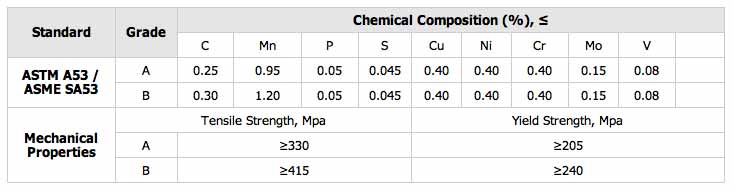

ASTM A53 Black and Hot Dip Galvanized Steel Pipe

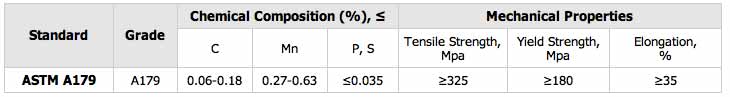

ASTM A179 Heat Exchanger and Condenser Tube

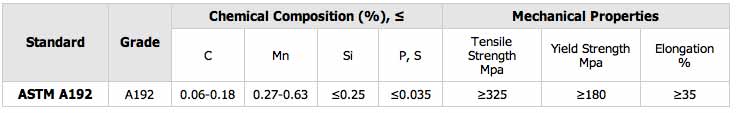

ASTM A192 High Pressure Boiler Tube

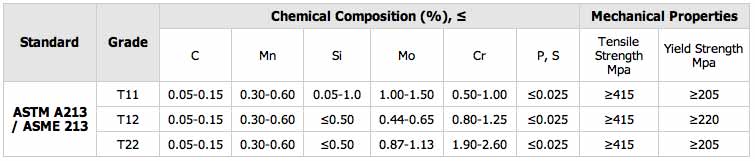

ASTM A213 Seamless Ferritic and Austenitic Alloy Steel Boiler, Superheater and Heat Exchanger Tube

We could also arrange the production according to other standard, such as ASTM A333, DIN 1629, DIN 2391, DIN 17175, EN10305, EN10216, etc.

Packaging of Seamless Steel Pipe:

Shanghai Metal Corporation Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

Process Method:

hot rolling or cold drawn.

Surface Coating:

varnish painted on pipe(black painting),anti-corrosion oil,

galvanized,or painting as customer's request.

Tubes and tool joints are welded using inertia or friction welding.

The tube is held stationary while the tool joint is revolved at high RPMs.

The tool joint is the firmly pressed onto the upset end of the tube while the tool joint is rotating.

The heat and force during this interaction weld the two together.

Once the "ram horns" or excess material is removed,

the weld line can only be seen under a microscope.

here

for

price

We will contact with you within 8 hours