- Oil Pipeline

- Water Pipeline

- Gas Pipeline

- Boat and Mooring Accessories

- Metal for Decoration

- Transformer Components

- Heat Exchanger Pipe

- Air Conditioning Spare Parts & Accessories

- Boiler

- Kitchen and Bathroom Appliance

- Metal for Household Appliance

- Solar Power Appliance

- Elevator

- Roofing and Ceiling

- Cable

- Tank

- Packaging

- Machinery and Equipment Spare Parts & Accessories

- Mold

- Automobile Parts

- Rail and Crane Rail

- Hardware Fitting

- Abrasive

- Road Construction Equipment

- Electronic Components

- Construction and Decoration Materials

- Doors and Windows

- Refrigerators

Carbon Steel Pipe/Tube for Oil Drill Pipe

Standard: ASTM A106, P235GH, EN10210, ASTM A572, AS/NZS 1163, AWWA C210, AWWA C200, etc.

Process Method: hot rolling, cold drawn or Welded.

we could many kinds of carbon steel pipes, including:

Seamless Steel Pipe, ERW Steel Pipe, SSAW Steel Pipe, LSAW Steel Pipe

Galvanized Steel Pipe, Square Steel Pipe, Rectangular Steel Pipe

API Steel Pipe, Oval Tube and so on.

Modern drill pipe is made from the welding of at least three separate pieces:

box tool joint, pin tool joint, and the tube.

The green tubes are received by the drill pipe manufacturer from the steel mill.

The ends of the tubes are then upset to increase the cross sectional area of the ends.

The tube end may be externally upset (EU), internally upset (IU), or internally and externally upset (IEU).

Standard max upset dimensions are specified in API 5DP,

but the exact dimensions of the upset are proprietary to the manufacturer.

After upsetting, the tube then goes through a heat treating process.

Drill pipe steel is commonly quenched and tempered to achieve high yield strengths

(135 ksi is a common tube yield strength).

Packing of Carbon Steel Pipe/Tube:

Shanghai Metal Corporation provides worldwide customers with standard seaworthy packaging to protect the goods during the delivery.

Fixed by steel strip in bundles, wrapped by plastic bag,

SMC packaging has multiply choices for each customer.

In addition, SMC packing attached with SMC label, indicating clearly about the product information.

Special requirement can be achieved for clients demand. Please feel free to contact us for further detail.

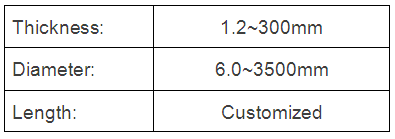

We provide wide range of sizes for different applications:

Surface Treatment: Oiling, Painting, Galvanizing, Anti-corrosion, Polished, etc.

If you have any requests or question, please contact us for more details.

here

for

price

We will contact with you within 8 hours