- Oil Pipeline

- Water Pipeline

- Gas Pipeline

- Boat and Mooring Accessories

- Metal for Decoration

- Transformer Components

- Heat Exchanger Pipe

- Air Conditioning Spare Parts & Accessories

- Boiler

- Kitchen and Bathroom Appliance

- Metal for Household Appliance

- Solar Power Appliance

- Elevator

- Roofing and Ceiling

- Cable

- Tank

- Packaging

- Machinery and Equipment Spare Parts & Accessories

- Mold

- Automobile Parts

- Rail and Crane Rail

- Hardware Fitting

- Abrasive

- Road Construction Equipment

- Electronic Components

- Construction and Decoration Materials

- Doors and Windows

- Refrigerators

分卷线

Width: 100mm-2000mm

Thickness: 0.2mm-12mm

SMC Equipment offers slitting lines of different designs to exactly suit the customer’s requirements of production capacity, high quality of

slit product, automation level, flexibility of operations and budget. The slitting line machine can incorporate latest technical innovations

for Slitter Heads.

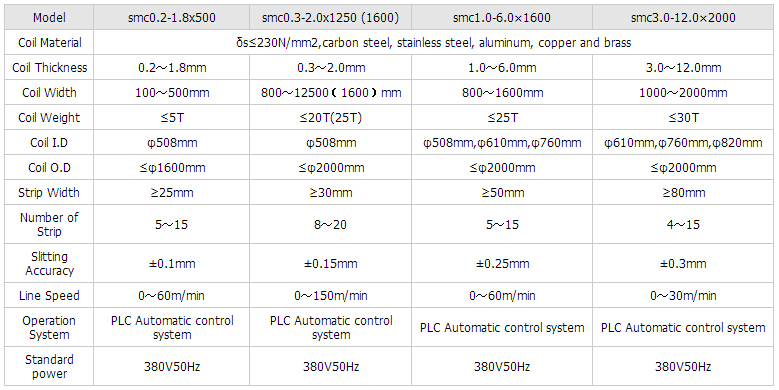

Specifications of Slitting Line:

1)The materials processed in Slitting lines are:

Carbon Steel

Stainless Steel

Aluminum

Copper and brass

2)Width: coil width ranges from 100mm to 2000mm; strip width up to 80mm

3)Coil Thickness: 0.2mm-12mm

4)Coil Weight: up to 30MT

5)Coil ID: 508mm-820mm

6)Coil OD: up to 2000mm

7)Line Speed: up to 150m/min

8)Operation System: PLC automatic control system

9)Standard Power: 380V50HZ

10)Applications: for slitting strips of carbon steel, stainless steel, aluminum, copper and brass.

Components of Slitting Line:

1) Coil car

2) Shear

3) Loop table

4) Uncoiler

5) Side guide

6) Tension station

7) Hold down roll

8) Slitter

9) Separator

10) Leveler

11) Scrap winders

12) Recoiler

Detailed Information of Slitting Line:

Advantages of Slitting Line:

1)High production and flow rates by consequent minimization of set-up times and high production speed, e.g. automatic coil feeding via coil height centering automatic cutter and tool change on the slitting shear simple and ergonomically exchange of separating shafts automatic loop control automated and fast strip feeding from the slitting shear to the recoiler through the tension unit coil strapping at the circumference on the turnstile via manual, semi-automatic and automatic strapping systems.

2)Precise cutting accuracy with the cutter shafts carried in multiple bearings.

3)Cutting with little burr simultaneously performing a high number of cuts on the slitting shear with minimum deflection of the cutter shaft.

4)High winding accuracy with increasing coil diameter by the movable tension unit for main operation without separating device at the recoiler.

5)Gentle treatment of the high-sensitive surfaces such as lacquered strip or bright annealed stainless steel by special braking systems, coordinated to the material surface.

6)High line availability and long lifetime by using exclusively components of prestigious manufacturers.

7)Fewer operating personnel due to a very high level of automation.

8)Prompt assistance in case of need by Online Teleservice per modern and at site by experts.

9)Flexible design of the lines in accordance to customer requirements, utilizing customer experience.

here

for

price

We will contact with you within 8 hours