- Oil Pipeline

- Water Pipeline

- Gas Pipeline

- Boat and Mooring Accessories

- Metal for Decoration

- Transformer Components

- Heat Exchanger Pipe

- Air Conditioning Spare Parts & Accessories

- Boiler

- Kitchen and Bathroom Appliance

- Metal for Household Appliance

- Solar Power Appliance

- Elevator

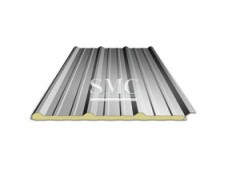

- Roofing and Ceiling

- Cable

- Tank

- Packaging

- Machinery and Equipment Spare Parts & Accessories

- Mold

- Automobile Parts

- Rail and Crane Rail

- Hardware Fitting

- Abrasive

- Road Construction Equipment

- Electronic Components

- Construction and Decoration Materials

- Doors and Windows

- Refrigerators

Hot Dip Galvanized Steel Sheet for Filter Housing

Thickness: 0.13mm-4.0mm

Width: 600mm - 1250mm

Length: Less than 12 meters

Introduction:

For more than 100 years, hot dip galvanized steel has been utilized extensively to combat corrosion in major

industrial environments including petro-chemical, transportation, and public utilities.

The hot -dip galvanized steel is more corrosion resistant than bare iron and steel, similar to steel, zinc corrodes

when exposed to the atmosphere; however,zinc corrodes at a rate approximately 1/30 of that for steel.

Specification of Hot Dip Galvanized Steel Sheet (GI Sheet):

1. Capacity: about 15,000 tons per month for the steel sheet and coil product

2. Grade: SGCC, DX51D, Q195, all according to the customer's request

3. Standard: JIS G3302 1998, ASTM A653M/A924M 2004, all according to the customer's request

4. Thickness: 0.13mm - 4.0mm, all available.

5. Width: 600mm - 1250mm , all available.

6.Standard Size: 3'x6', 4'x4', 4'x5', 4'x6', 4'x8', 5'x10', etc

7. Elongation: Min. 7%

8. Zinc coating weight: 60g/m2-600g/m2 (z180, z200, z275, z275, z300)

9. Tensile strength: 28.1 - 49.2kgf/mm2

10. Edge: mill edge, cut edge

11.Types of Galvanized Sheet Metal: (all of our patterns are custom-manufactured.)

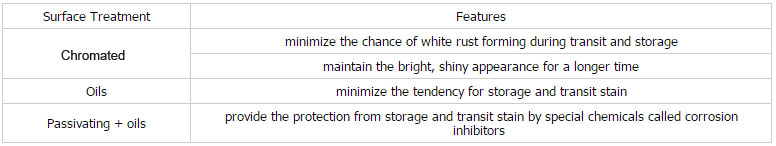

12.Surface Treatment:

13.Spangle:

Different Types of Hot Dip Galvanized Steel Sheet (GI Sheet):

We are able to make galvanized sheet to further processsing, such as embossed sheet metal, checker steel sheet, perforated steel metal, corrugated roof sheet, and prepainted galvanized steel sheet. We provide various patterns for those different types. Please check the metal sheet types's table below. All of our metal sheet types are custom-manfactureed.

The GALVANIZED STEEL SHEET PRODUCTS forming process consists of three basic steps: surface preparation,galvanizing and inspection.

Surface preparation consists of three steps: degreasing, acid pickling and fluxing.

Galvanizing is completely immersed in a bath of molten zinc.

A variety of simple physical and laboratory tests may be performed to determine thickness,uniformity,adherence, and appearance.

The GALVANIZED STEEL SHEET PRODUCTS forming process consists of three basic steps: surface preparation,galvanizing and inspection.

Surface preparation consists of three steps: degreasing, acid pickling and fluxing.

Galvanizing is completely immersed in a bath of molten zinc.

A variety of simple physical and laboratory tests may be performed to determine thickness,uniformity,adherence, and appearance.

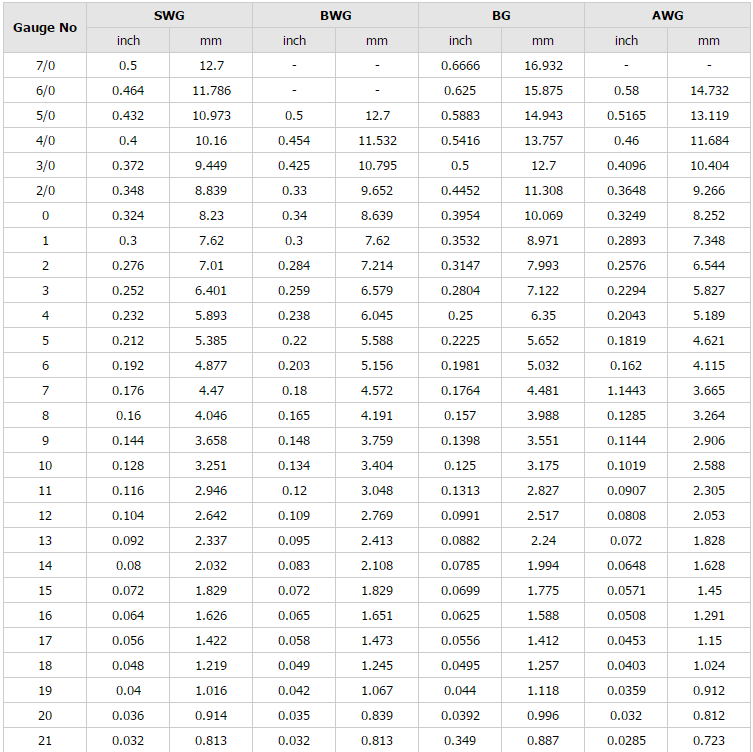

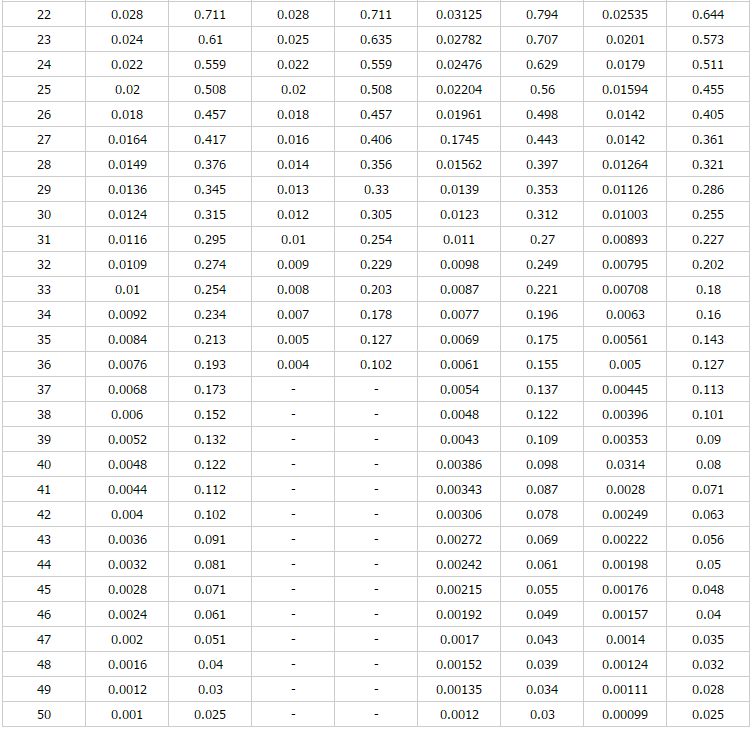

Shanghai Metal Corporation Standard Sheet Metal Gauge:

Packaging for Hot Dip Galvanized Steel Sheet (GI Sheet):

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

Application of Hot Dip Galvanized Steel Sheet (GI Sheet):

1.Construction and building: roofing; ventilating duct; handrail; partition panel,etc.

2.Further processing: coating base plate

3.Electric appliance: Refrigerator; washing machine; recorder; microwave, etc.

here

for

price

We will contact with you within 8 hours