- Oil Pipeline

- Water Pipeline

- Gas Pipeline

- Boat and Mooring Accessories

- Metal for Decoration

- Transformer Components

- Heat Exchanger Pipe

- Air Conditioning Spare Parts & Accessories

- Boiler

- Kitchen and Bathroom Appliance

- Metal for Household Appliance

- Solar Power Appliance

- Elevator

- Roofing and Ceiling

- Cable

- Tank

- Packaging

- Machinery and Equipment Spare Parts & Accessories

- Mold

- Automobile Parts

- Rail and Crane Rail

- Hardware Fitting

- Abrasive

- Road Construction Equipment

- Electronic Components

- Construction and Decoration Materials

- Doors and Windows

- Refrigerators

Hastelloy B-3

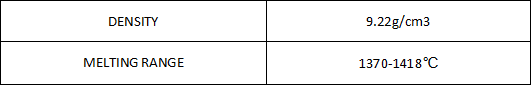

Density: 9.22g/cm3

Melting Range: 1370-1418℃

Physical properties:

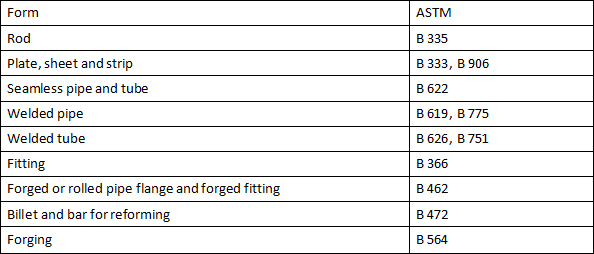

Products description:

Equivalent designationsUNS N10675

DIN W. Nr. 2.4600

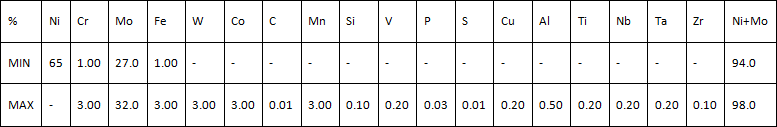

Chemical Composition:

Features:

Hastelloy B-3 has outstanding resistance to hydrochloric acid at all concentrations and temperatures. It also resists sulfuric, phosphoric, formic, acetic acids and other nonoxidizing media. It has excellent resistance to pitting corrosion, stress corrosion cracking, and knife line and weld heat-affected zone attack. Hastelloy B-3 has greater thermal stability than Hastelloy B-2.

Exceptional resistance to HCl and H2SO4 and enhanced structural stability

HASTELLOY® B-3® alloy (UNS N10675) exhibits extremely high resistance to pure hydrochloric, hydrobromic, and sulfuric acids. Furthermore, it has greatly improved structural stability compared with previous B-type alloys, leading to fewer concerns during welding, fabrication, and service.

Like other nickel alloys (in the mill annealed condition), it is ductile, can be formed and welded, and resists stress corrosion cracking in chloride-bearing solutions. Also, it is able to withstand fluoride-bearing media and concentrated sulfuric acid, both of which result in damage to zirconium alloys.

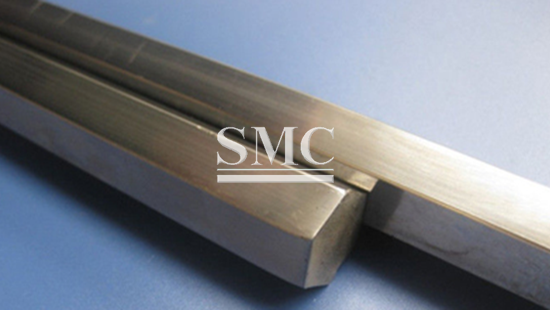

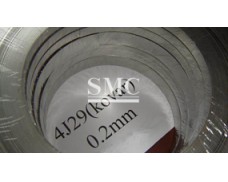

HASTELLOY® B-3® alloy is available in the form of plates, sheets, strips, billets, bars, wires, pipes, tubes, and coated electrodes. It is used in numerous chemical process industry (CPI) applications, especially in the construction of reaction vessels for pure, reducing acid service.

Applications:

Hastelloy B-3 is suitable for the applications where Hastelloy B-2 is required. Like Hastelloy B-2, Hastelloy B-3 should not be used in the presence of ferric or cupric salts as these salts may cause rapid corrosion attack.

here

for

price

We will contact with you within 8 hours