- Oil Pipeline

- Water Pipeline

- Gas Pipeline

- Boat and Mooring Accessories

- Metal for Decoration

- Transformer Components

- Heat Exchanger Pipe

- Air Conditioning Spare Parts & Accessories

- Boiler

- Kitchen and Bathroom Appliance

- Metal for Household Appliance

- Solar Power Appliance

- Elevator

- Roofing and Ceiling

- Cable

- Tank

- Packaging

- Machinery and Equipment Spare Parts & Accessories

- Mold

- Automobile Parts

- Rail and Crane Rail

- Hardware Fitting

- Abrasive

- Road Construction Equipment

- Electronic Components

- Construction and Decoration Materials

- Doors and Windows

- Refrigerators

Incoloy 800

Equivalent designations: Incoloy 800, UNS N08800, NS111, DIN W. Nr. 1.4876.

Application: heat-treating equipment, chemical and petrochemical processing, nuclear power plants.

Place of Origin: Shanghai, China (Mainland)

Application: heat-treating equipment, chemical and petrochemical processing, nuclear power plants.

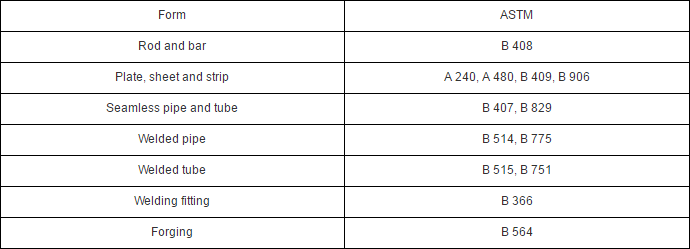

Product list:

Specification:

Wire: 0.01-10mmStrip: 0.05*5.0-5.0*250mm

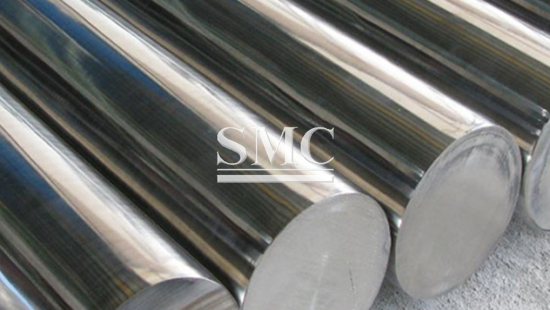

Bar: φ4-50mm; Length 2000-5000mm

Pipe: φ6-273mm;δ1-30mm; Length 1000-8000mm

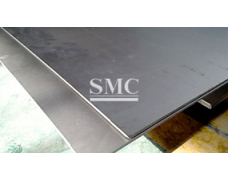

Sheet: δ0.8-36mm; Width 650-2000mm; Length 800-4500mm

Model Number: Incoloy 800

Brand Name: SMCShape: Forging

Standard: ASTM ASME

Certification: ISO 9001:2008

Color: Nickel Nature

Packing: Common sea freight wooden case package/ Also can be customized

Payment: L/C,T/T

Delivery: Usually sample lead time is 7 days after payment has been confirmed.

Incoloy 800 has good rupture and creep strength and excellent resistance to oxidation, carburization and sulfidation at temperatures up to 816℃. It also resists general corrosion by many aqueous media. For Applications requiring higher stress rupture and creep properties, especially at temperatures above 816℃, Incoloy 800H and 800HT are recommended. Incoloy 800 is readily formed, welded and machined.

1. Produces process

Raw material→ Smelting→ Drawing→ Rolling→ Annealing→ Finished product→ Detection→ Packing→ Shipping

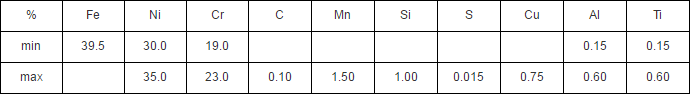

2. Chemical composition

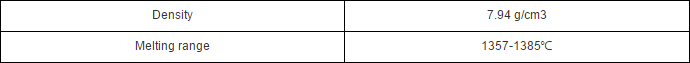

3. Physical properties

Characters:

Incoloy 800 offers general corrosion resistance to many aqueous media and, by virtue of its content of nickel, resists stress corrosion cracking. At elevated temperatures it offers resistance to oxidation, carburization, and sulfidation along with rupture and creep strength. For applications requiring greater resistance to stress rupture and creep, especially at temperatures above 1500°F (816°C), INCOLOY alloys 800H and 800HT are used.

Application:

Chemical and petrochemical process piping, heat exchangers, furnace components, carburizing equipment, heating-element sheathing, and nuclear power steam-generator tubing.

here

for

price

We will contact with you within 8 hours