- Oil Pipeline

- Water Pipeline

- Gas Pipeline

- Boat and Mooring Accessories

- Metal for Decoration

- Transformer Components

- Heat Exchanger Pipe

- Air Conditioning Spare Parts & Accessories

- Boiler

- Kitchen and Bathroom Appliance

- Metal for Household Appliance

- Solar Power Appliance

- Elevator

- Roofing and Ceiling

- Cable

- Tank

- Packaging

- Machinery and Equipment Spare Parts & Accessories

- Mold

- Automobile Parts

- Rail and Crane Rail

- Hardware Fitting

- Abrasive

- Road Construction Equipment

- Electronic Components

- Construction and Decoration Materials

- Doors and Windows

- Refrigerators

Monel 400

Equivalent Designations: Monel 400, UNS N04400, DIN W. Nr. 2.4360, 2.4361

Model Number: Monel 400

Place of Origin: Shanghai, China (Mainland)

Application: Chemical Industry, water tanks, engineering equipment

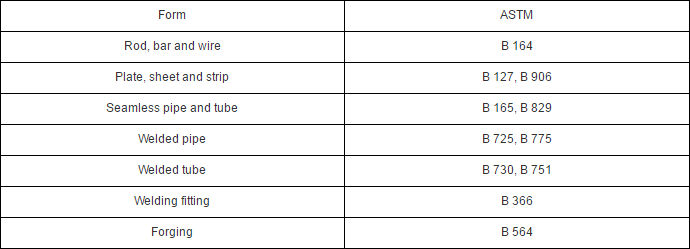

Product list:

Wire: 0.01-10mm

Strip: 0.05*5.0-5.0*250mm

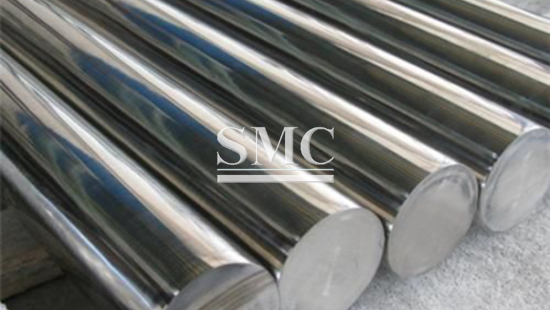

Bar: φ4-50mm; Length 2000-5000mm

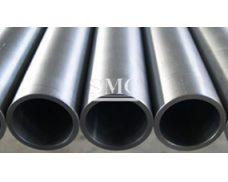

Pipe: φ6-273mm; δ1-30mm; Length 1000-8000mm

Sheet: δ 0.8-36mm; Width 650-2000mm; Length 800-4500mm

Model Number: Monel 400

Brand Name: SMC

Shape: Forging

Standard: ASTM ASME

Certification: ISO 9001:2008

Color: Nickel Nature

Packing: Common sea freight wooden case package/ Also can be customized

Payment: L/C,T/T

Delivery: Usually sample lead time is 7 days after payment has been confirmed.

Monel 400 has excellent resistance to corrosion by many reducing media such as sulfuric and hydrochloric acids. It is generally more resistant to corrosion by oxidizing media than higher copper alloys. Monel 400 resists pitting and stress corrosion cracking in most fresh and industrial waters. It has good resistance in flowing seawater, but under stagnant conditions, pitting and crevice corrosion is induced. Monel 400 is probably the most resistant to hydrofluoric acid in all concentrations up to the boiling point, of all engineering alloys. Monel 400 is notable for its toughness, it does not show embrittlement tendency at cryogenic temperatures. It is work hardenable.

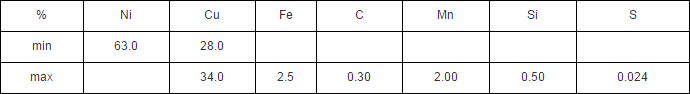

Chemical composition

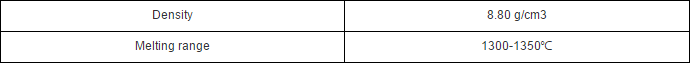

Physical properties

Character

Resistant to seawater and steam at high temperatures.

Excellent resistance to rapidly flowing brackish water or seawater.

Excellent resistance to stress corrosion cracking in most freshwaters.

Particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated.

Offers some resistance to hydrochloric and sulfuric acids at modest temperatures and concentrations, but is seldom the material of choice for these acids.

Excellent resistance to neutral and alkaline salt.

Resistance to chloride induced stress corrosion cracking.

Good mechanical properties from sub-zero temperatures up to 1020° F.

High resistance to alkalis.

Application

Marine engineering.

Chemical and hydrocarbon processing equipment.

Gasoline and freshwater tanks.

Crude petroleum stills.

De-aerating heaters.

Boiler feed water heaters and other heat exchangers.

Valves, pumps, shafts, fittings, and fasteners.

Industrial heat exchangers.

Chlorinated solvents.

Crude oil distillation towers.

here

for

price

We will contact with you within 8 hours