- Oil Pipeline

- Water Pipeline

- Gas Pipeline

- Boat and Mooring Accessories

- Metal for Decoration

- Transformer Components

- Heat Exchanger Pipe

- Air Conditioning Spare Parts & Accessories

- Boiler

- Kitchen and Bathroom Appliance

- Metal for Household Appliance

- Solar Power Appliance

- Elevator

- Roofing and Ceiling

- Cable

- Tank

- Packaging

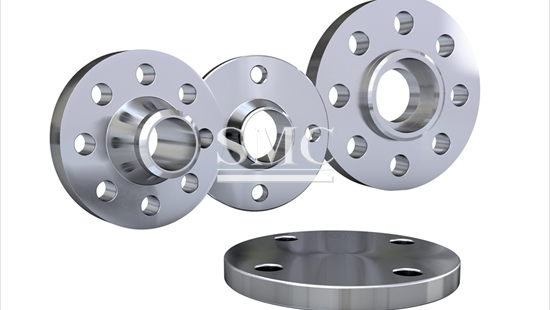

- Machinery and Equipment Spare Parts & Accessories

- Mold

- Automobile Parts

- Rail and Crane Rail

- Hardware Fitting

- Abrasive

- Road Construction Equipment

- Electronic Components

- Construction and Decoration Materials

- Doors and Windows

- Refrigerators

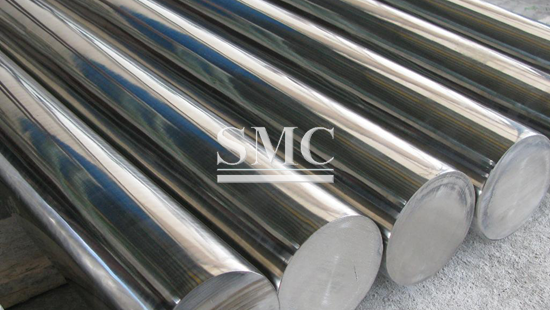

Nickel 201

Equivalent Designations: UNS N02201, DIN W. Nr. 2.4061, 2.4068

Nickel 201 (UNS N02201/W.Nr. 2.4061 and 2.4068) is the low-carbon version of Nickel 200. Typical applications are caustic evaporators, combustion boats, plater bars, and electronic components.

Nickel 201, because of its low base hardness and lower work-hardening rate, is particularly suited for spinning and cold forming. It is preferred to Nickel 200 for applications involving exposure to temperatures above 600°F (315°C).

Equivalent designations

UNS N02201

DIN W. Nr. 2.4061, 2.4068

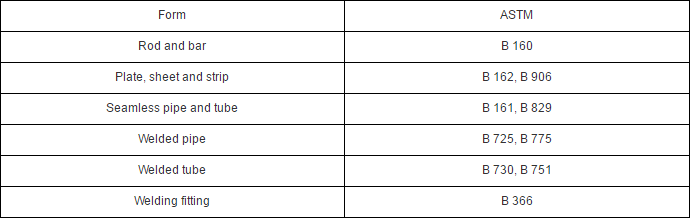

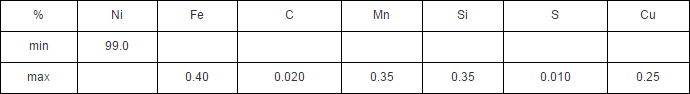

Chemical composition:

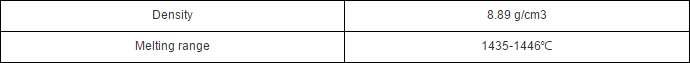

Physical properties:

Features:

Nickel 201 is the low-carbon version of Nickel 200. Because of its low carbon content, Nickel 201 is not subject to embrittlement by intergranularly precipitated carbon or graphite when exposed to temperatures of 315 to 760℃ for prolonged time if carbonaceous materials are not in contact with it. Therefore, it is a substitute for Nickel 200 in Applications above 315℃.

However it does suffer from intergranular embrittlement by sulfur compounds at temperatures above 315℃. Sodium peroxide can be used to change them to sulfates to counteract their effect.

Applications:

1. Food processing equipment, salt refining equipment.

2. Mining and marine mining.

3. Equipment required for the manufacture of industrial sodium hydroxide at high temperatures above 300 ° C.

4. Production of organic or inorganic chlorides and fluorides: resistance to chlorine and fluorine gases.

Nuclear reactor.

6. Heat treatment furnace in the curved bottles and parts, especially in the carbonation and nitriding atmosphere.

7. Catalytic Regenerators in petrochemical production It is recommended to use alloy 600 for applications with temperatures above 700 ° C for longer service life.

8. Nickel201 is a purely commercial nickel with very low carbon content and has been approved for use in high temperature environments up to 1230 ° C

here

for

price

We will contact with you within 8 hours