- Oil Pipeline

- Water Pipeline

- Gas Pipeline

- Boat and Mooring Accessories

- Metal for Decoration

- Transformer Components

- Heat Exchanger Pipe

- Air Conditioning Spare Parts & Accessories

- Boiler

- Kitchen and Bathroom Appliance

- Metal for Household Appliance

- Solar Power Appliance

- Elevator

- Roofing and Ceiling

- Cable

- Tank

- Packaging

- Machinery and Equipment Spare Parts & Accessories

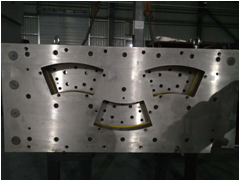

- Mold

- Automobile Parts

- Rail and Crane Rail

- Hardware Fitting

- Abrasive

- Road Construction Equipment

- Electronic Components

- Construction and Decoration Materials

- Doors and Windows

- Refrigerators

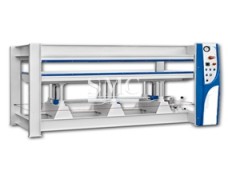

冲切机

Model: SMC-CM-850

Max Paper Width: 850mm

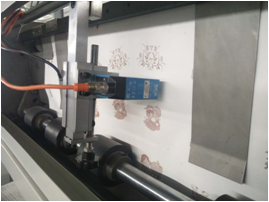

Cutting Precision: 0.20mm

Die Punch Machine for Cup Paper SMC-CM-850

including:

FD850 roll die punching machineX1

Metal Die CutterX1

Air expansion shaftX1

EXTRA MOLDX1

Max Paper Width: 850mm

Cutting Precision: 0.20mm

Paper Gram Weight: 150-350g/㎡Production Capacity: 280-320times/min

Air Pressure Requirement: 0.5Mpa

Air Pressure Consumption: 0.25m³/min

Weight: 4.0T

Max Roller Diameter: 1500

Total Power: 10KW

Dimension: 3800x1900x1900mm

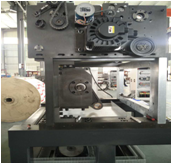

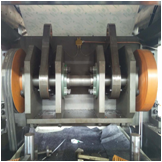

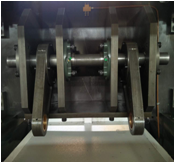

Main structure

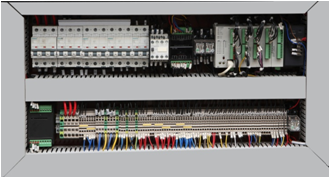

1. It adopts micro-computer, human-computer control interface, servo positioning, and we make the wallboard, base much stronger than others, it gurantees that when the machine runs with 300 strokes/min, you won’t feel that machine is shaking.

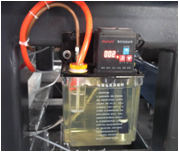

2.Lubri cation System: Adopts forced lubrication system to ensure main driving oil supply regularly and reduce friction and prolong the machine life, you could set it to lubricate one time every 10 minutes.

3. The die-cutting force is provided by a 7.5KW inverter motor driver. It is not only power-saving, but also can realize the stepless speed adjustment, especially when coordinate with the extra large flywheel, which make the die-cutting force strong and steady, and the electricity can be further reduced.

here

for

price

We will contact with you within 8 hours