- Oil Pipeline

- Water Pipeline

- Gas Pipeline

- Boat and Mooring Accessories

- Metal for Decoration

- Transformer Components

- Heat Exchanger Pipe

- Air Conditioning Spare Parts & Accessories

- Boiler

- Kitchen and Bathroom Appliance

- Metal for Household Appliance

- Solar Power Appliance

- Elevator

- Roofing and Ceiling

- Cable

- Tank

- Packaging

- Machinery and Equipment Spare Parts & Accessories

- Mold

- Automobile Parts

- Rail and Crane Rail

- Hardware Fitting

- Abrasive

- Road Construction Equipment

- Electronic Components

- Construction and Decoration Materials

- Doors and Windows

- Refrigerators

不锈钢焊接三通

Material: 304, 304L, 321, etc.

Standard: ASME, MSS, HG, etc

Pressure: 3000#, 6000#, 9000#

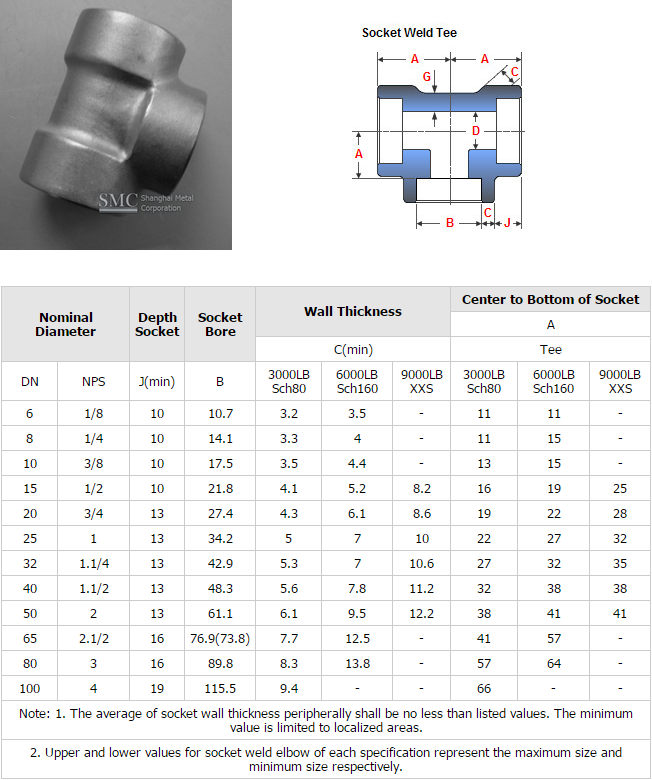

Specifications of Stainless Steel Socket Weld Tee:

1. Size: 1/8 inch-4 inch; DN6-DN100

2. Pressure: 3000#, 6000#, 9000#

3. Standard: GB/T14383-2008

SH/T3410-1996(DN=10-80mm SCH80, sCH160)

HG/T21634-1998

ASME B16.11-2005

BS3799-1974

JIS B2316-2007

4. Manufacture process: Forging or machining

5. Material: 304-304H-304L-304N-304LN 316-316H-316L-316N-316LN 321-321H-347-347H

Parameter of Stainless Steel Socket Weld Tee:

Package of Stainless Steel Pipe Fitting:

The stainless steel pipe fitting products are packed according to the international standards and regulations as well as to customer's requests. We would take great care to avoid any damage during storage or transportation of the stainless steel flanges.

Application of Stainless Steel Socket Weld Tee:

1. SW Fittings are family of high pressure fittings are used in various industrial processes.

2. They are used for lines conveying flammable, toxic or expensive material where no leakage can be permitted, and for steam 300 to 600 PSI.

3. They are used only in conjunction with ASME Pipe and are available in the same size range.

4. They are used in areas where pipe-work is permanent and are designed to provide good flow characteristics.

5. They are produced to several ASTM standards and are manufactured in accordance with ASME B16.11. The B16.11 standard covers pressure-temperature ratings, dimensions, tolerances, marking, and material requirements for forged carbon and alloy steel. Acceptable material forms are forgings, bars, seamless pipe, and seamless tubes which conform to the fittings chemical compositions, melting practices, and mechanical property requirements of ASTM A105, A182, or A350.

6. They are available in three pressure ratings: 3000lbs, 6000lbs and 9000lbs.

Feature of Stainless Steel Socket Weld Tee:

1. The pipe need not be beveled for weld preparation.

2. Temporary tack welding is no needed for alignment, because in principle the fitting ensures proper alignment.

3. The weld metal can not penetrate into the bore of the pipe.

4. They can be used in place of threaded fittings, so the risk of leakage is much smaller.

5. Radiography is not practical on the fillet weld; therefore correct fitting and welding is crucial. The fillet weld may be inspected by surface examination, magnetic particle (MP), or liquid penetrant (PT) examination methods.

6. Construction costs are lower than with butt-welded joints due to the lack of exacting fit-up requirements and elimination of special machining for butt weld end preparation.

here

for

price

We will contact with you within 8 hours