- Oil Pipeline

- Water Pipeline

- Gas Pipeline

- Boat and Mooring Accessories

- Metal for Decoration

- Transformer Components

- Heat Exchanger Pipe

- Air Conditioning Spare Parts & Accessories

- Boiler

- Kitchen and Bathroom Appliance

- Metal for Household Appliance

- Solar Power Appliance

- Elevator

- Roofing and Ceiling

- Cable

- Tank

- Packaging

- Machinery and Equipment Spare Parts & Accessories

- Mold

- Automobile Parts

- Rail and Crane Rail

- Hardware Fitting

- Abrasive

- Road Construction Equipment

- Electronic Components

- Construction and Decoration Materials

- Doors and Windows

- Refrigerators

铝阳极氧化管

Grade: 6063, 6061, 6060, 6005,6005A,etc

Temper: T4, T5 or T6

Length: 1m-12m

In our daily life, the Anodized Aluminum Tube is widely used in construction, automobile and other industry.

Shanghai Metal Corporation has over 10-year experiences in aluminum processing and manufacturing.

We are glad to customize products according to your request.

specifications of Anodized Aluminum Tube:

1. Grade : 6063, 6061, 6060, 6005, 6005A, etc

2. Temper :T4, T5 or T6

3. Various colors :sliver, bronze, black, gold, blue, gray, champagne, bright, etc

4. Machining :cutting, punching, drilling, tapping, milling, bending

5. Wall thickness : 0.2mm above or custom

6. Surface Treatment : Anodized,brushed,mill finished,polished, powder coated, sand blast, etc

7. Length :1m-12m

8. Outer Diameter : 10mm above

Applications of Anodized Aluminum Tube

1.Agricultural

2.Electronics

3.Tower buildings

4.Material

5.Aviation fixtures

6.Automobile

7.Mechanical

8.Trucks

9.Ships

10.Aluminum window

11.Door

12.Curtain wall

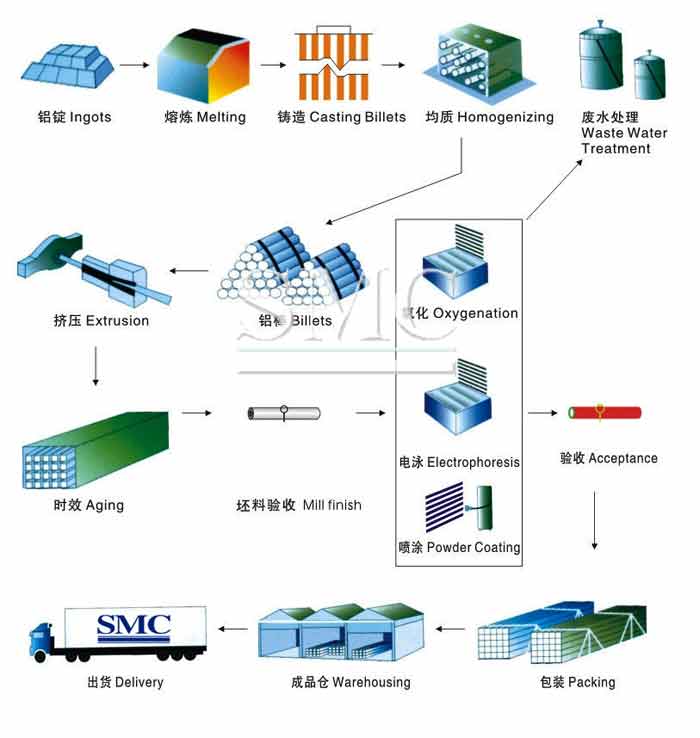

Processing Of Aluminum Tube:

Package of Anodized Aluminum Tube

Shanghai Metal Corporation Products are packed and labeled according to the regulations and customer's requests.

Great care is taken to avoid any damage which might be caused during storage or transportation.

In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)SMC Standard

2)Customization

1. Q: What is the Benefits of Anodizing?

R: The unique anodized finish is the only one in the metals industry that satisfies each of the factors that must be considered when selecting a high performance aluminum finish:

Durability. Most anodized products have an extremely long life span and offer significant economic advantages through maintenance and operating savings. Anodizing is a reacted finish that is integrated with the underlying aluminum for total bonding and unmatched adhesion.

Color Stability. Exterior anodic coatings provide good stability to ultraviolet rays, do not chip or peel, and are easily repeatable.

Ease of Maintenance.Scars and wear from fabrication, handling, installation, frequent surface dirt cleaning and usage are virtually non-existent. Rinsing or mild soap and water cleaning usually will restore an anodized surface to its original appearance. Mild abrasive cleaners can be used for more difficult deposits.

Aesthetics.Anodizing offers a large increasing number of gloss and color alternatives and minimizes or eliminates color variations. Unlike other finishes, anodizing allows the aluminum to maintain its metallic appearance.

Cost.A lower initial finishing cost combines with lower maintenance costs for greater long-term value.

Health and Safety.Anodizing is a safe process that is not harmful to human health. An anodized finish is chemically stable, will not decompose; is non-toxic; and is heat-resistant to the melting point of aluminum (1,221 degrees F.)

Since the anodizing process is a reinforcement of a naturally occurring oxide process, it is non-hazardous and produces no harmful or dangerous by-products.

2. Q: Are the prices the same for all the colors with same surface treatment ?

R: Not yet, about Powder coating, the bright-coloured will higher than white or gray; about the Anodizing, colorful will higher than silver, and black higher than colorful.

3. Q: What is the main market?

R: Our main foreign markets are Asia, Africa, America, Europe.

4. Q: Which way do you calculate the weight by?

R: We calculae it according to the theoretical weight or the actual weight, it depends on the clients requirements.

here

for

price

We will contact with you within 8 hours