- Oil Pipeline

- Water Pipeline

- Gas Pipeline

- Boat and Mooring Accessories

- Metal for Decoration

- Transformer Components

- Heat Exchanger Pipe

- Air Conditioning Spare Parts & Accessories

- Boiler

- Kitchen and Bathroom Appliance

- Metal for Household Appliance

- Solar Power Appliance

- Elevator

- Roofing and Ceiling

- Cable

- Tank

- Packaging

- Machinery and Equipment Spare Parts & Accessories

- Mold

- Automobile Parts

- Rail and Crane Rail

- Hardware Fitting

- Abrasive

- Road Construction Equipment

- Electronic Components

- Construction and Decoration Materials

- Doors and Windows

- Refrigerators

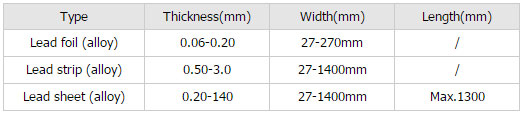

Thickness: 0.20-140 mm

Width: 27-1400 mm

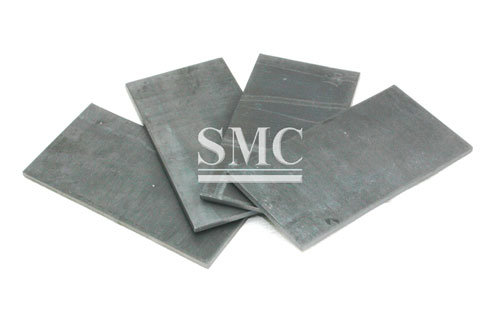

Specifications of Lead Alloy Sheet:

1. Thickness: 0.20-140 mm

2. Width: 27-1400 mm

3. Standard: ASTM B 29, federal specification QQ-L-171, German standard DIN 1719, British specification BS 334,

Canadian Standard CSA-HP2, and Australian Standard 1812.

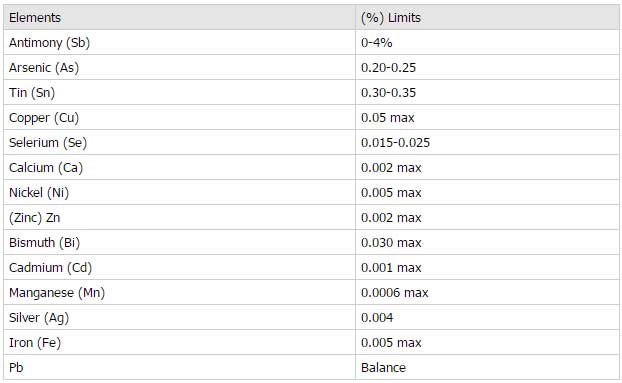

4. Chemical composition:

Pb : max.99.999%

Sb : 0.00-4%

Sn : 0.00 to 6% see solder foils

(Further ally elements can be customized according to requirements.)

Characteristics of Lead Alloy Sheet:

- Very soft: Without support, it can sag and become distorted

- Dense

- Durable

- Malleable

- Low melting point

- Long life-span (in milder climates, lead roofs have been known to last 200-300 years)

- Generally corrosion-resistant - has little to no reaction with most compounds and solutions.

- Resistant to corrosion by most acids including chromic,sulfuric, sulfurous and phosphoric acids.

- Corrosive to alkalis (such as lime mortar, portland cement and uncured concrete), tannic acid found in wood,

and radiation.

- Corrosive to hydrochloric, hydrofluoric, acetic, formic and nitric acids.

etc.

Chemical Composition of Lead Alloy Sheet:

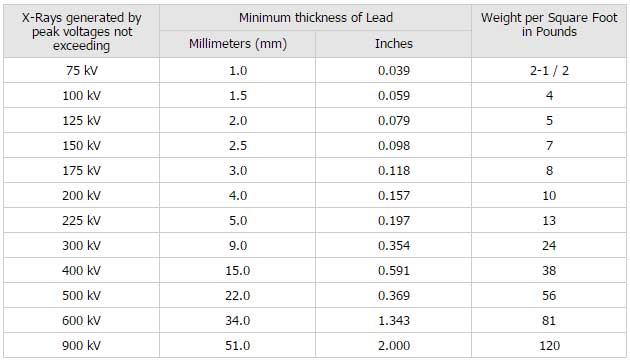

Recommended Thickness of Lead Shielding of X-Ray Rooms:

Packaging of Indium Foil/Indium Ribbon:

Shanghai Metal Corporation Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)SMC Standard

2)Customization

Applications of Lead Alloy Sheet:

- X-ray shielding in the medical and dental field

- Lead shielding for personal protection

- Nuclear shielding in the power generation industry

- Nuclear shielding for research in industry and university

- Radiation shielding for the military

- X-ray shielding to protect workers at security x-ray machines

- Sheet roofing

- Decorative spandrels

- Gutters, leader heads and downspouts

- Cast decorative features and sculpture

- Cupolas, spires and mullions

- Sheathing for cables

- Sheet lead partitions (good for noise reduction)

- Pads for vibrating machinery

- To waterproof ironwork where the iron is fitted into stone.

- Ballast, gaskets, type metal, terneplate and foil

- Building construction materials (such as sheet, pipe, solder, and wool for caulking)

- Materials used in marine power,

- Manufacture of batteries , paint, shells, welding materials, bearing materials, caulking materials,etc.

- Lead-based paint: Red lead is typically used as a corrosion inhibitor for use on iron. White lead is used more frequently in commercial applications. White lead is not intended for use on iron

- Its use will increase corrosion, especially on wrought iron.

etc.

here

for

price

We will contact with you within 8 hours