- Oil Pipeline

- Water Pipeline

- Gas Pipeline

- Boat and Mooring Accessories

- Metal for Decoration

- Transformer Components

- Heat Exchanger Pipe

- Air Conditioning Spare Parts & Accessories

- Boiler

- Kitchen and Bathroom Appliance

- Metal for Household Appliance

- Solar Power Appliance

- Elevator

- Roofing and Ceiling

- Cable

- Tank

- Packaging

- Machinery and Equipment Spare Parts & Accessories

- Mold

- Automobile Parts

- Rail and Crane Rail

- Hardware Fitting

- Abrasive

- Road Construction Equipment

- Electronic Components

- Construction and Decoration Materials

- Doors and Windows

- Refrigerators

紫铜&黄铜管件、型材

电极帽

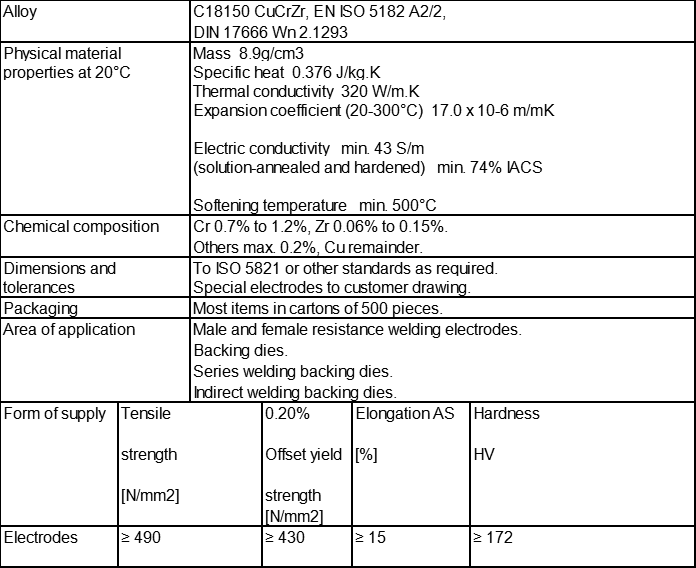

Specific heat: 0.376 J/kg.K

Thermal conductivity: 320 W/m.K

Product Detail

Electrode caps and shanks are two-part electrodes statutable for the straight electrodes and can offer major economies.

SMC offers cold-formed cap electrodes in full range of nose design, alloys and sizes. Caps are cold forged without additional machining, making them distinguished for their metallurgical property (high conductivity and resistance to deformation), consistent performance and long life.

The lower percentage of chrome in comparison to the standard Class 2 CuCr material and the addition of Zr to this Copper alloy discourage the alloying affect of zinc and copper to form brass on the electrode face and help to prevent sticking.

The universal cap electrodes for reliable resistance welding of light-to-medium gauge coated and uncoated steels. Produced by proprietary billet casting process, freedom from oxygen allows us to alloy the copper with the optimum levels of chrome and zirconium. Electrodes are cold headed or machined to suit the required shape. We have long history of supplying high quality CuCrZr.

SMC offers cold-formed cap electrodes in full range of nose design, alloys and sizes. Caps are cold forged without additional machining, making them distinguished for their metallurgical property (high conductivity and resistance to deformation), consistent performance and long life.

The lower percentage of chrome in comparison to the standard Class 2 CuCr material and the addition of Zr to this Copper alloy discourage the alloying affect of zinc and copper to form brass on the electrode face and help to prevent sticking.

The universal cap electrodes for reliable resistance welding of light-to-medium gauge coated and uncoated steels. Produced by proprietary billet casting process, freedom from oxygen allows us to alloy the copper with the optimum levels of chrome and zirconium. Electrodes are cold headed or machined to suit the required shape. We have long history of supplying high quality CuCrZr.

Click here for price

Clickhere

for

price

We will contact with you within 8 hours