- Oil Pipeline

- Water Pipeline

- Gas Pipeline

- Boat and Mooring Accessories

- Metal for Decoration

- Transformer Components

- Heat Exchanger Pipe

- Air Conditioning Spare Parts & Accessories

- Boiler

- Kitchen and Bathroom Appliance

- Metal for Household Appliance

- Solar Power Appliance

- Elevator

- Roofing and Ceiling

- Cable

- Tank

- Packaging

- Machinery and Equipment Spare Parts & Accessories

- Mold

- Automobile Parts

- Rail and Crane Rail

- Hardware Fitting

- Abrasive

- Road Construction Equipment

- Electronic Components

- Construction and Decoration Materials

- Doors and Windows

- Refrigerators

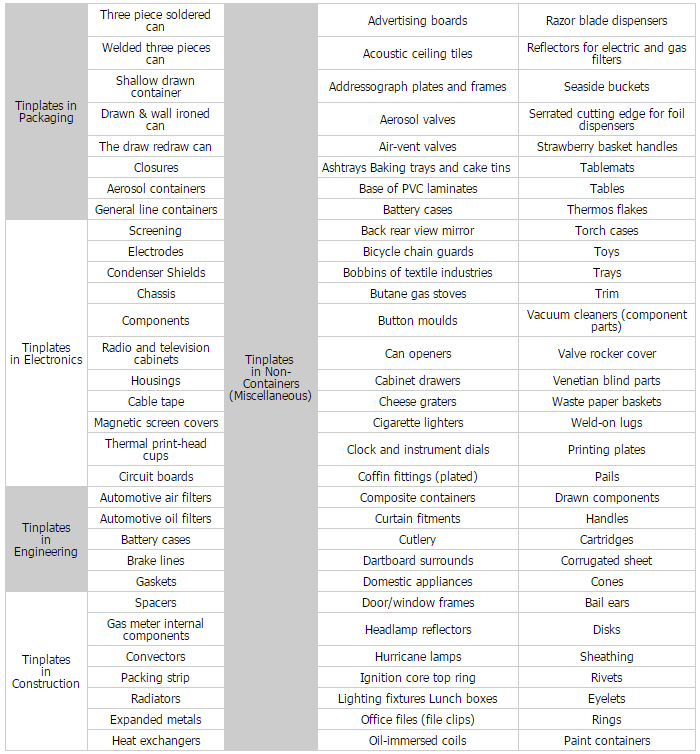

Tin Plate, Tinplate Coil For Packaging

Thickness: 0.14mm-0.50mm

Width: ≤1050mm

Tin Coating: 1.1g/m2-8.4g/m2

Specification of Tin Plate, Tinplate Coil:

1) Capacity: about 58,000 tons per year for tin plate products.

2) Standard: Passiviation 300 & 311, EN10202, EN10203, JIS G3303, ASTM A624, ASTM626

3) Raw material: MR, SPCC

4) Thickness: from 0.18mm to 0.50mm, all available

5) Width: from 200mm to 1050mm, all available

6) Hardnss:T1-T5,DR-8, DR-9, DR-9M

7) Tin coating weight: 1.1g/m2-8.4g/m2

8) Surface: bright finish, stone, matte, silver

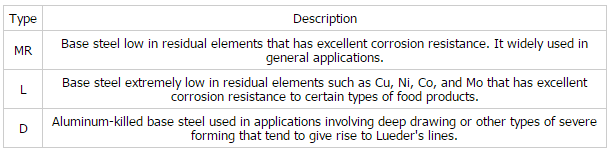

9) Min trial order: 5 tons per each thickness, 1x20' per delivery Steel Type

10) Steel Type

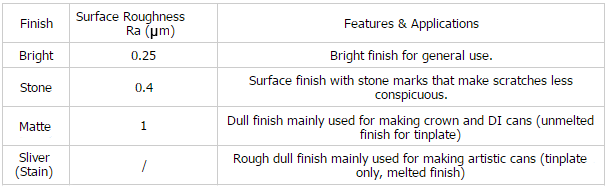

Surface Finish of Tin Plate, Tinplate Coil:

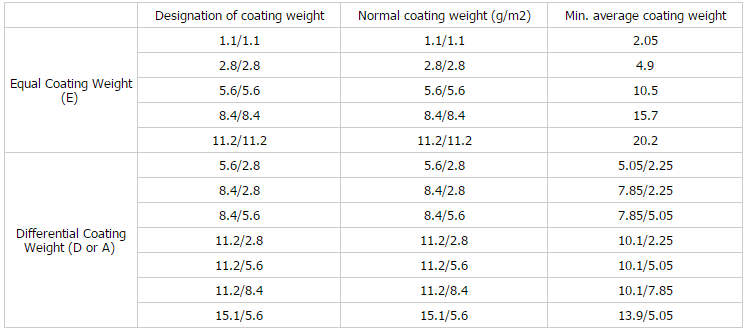

Tin Coating Weight of Tin Plate, Tinplate Coil:

Advantages of Tinplate-A packaging artist: hygienic, safe, and infinitely creative

The benefits of tinplate as a packaging material are manifold:

Low weight and high strength - making tinplate packaging easy to ship and store.

Optimum protection of food products - from impurities, bacteria, moisture, light, and odours.

Unsurpassed safety of tinplate containers for chemical/technical products.

Tinplate is an eco-friendly packaging material offering 100 percent recyclability - any number of times, and without quality loss.

Compared with other materials such as aluminum, tinplate offers significant cost benefits.

Material savings through down-gauging. Tinplate is ideally suited for the drawing and wall ironing (DWI) process used in the production of beverage cans. Reductions to just one-third of the original sheet thickness are feasible (special deep-drawing grades).

Direct printing, embossing and new shaping techniques increase the material's marketing potential: tinplate packaging attracts consumer attention and favorably influences purchasing decisions. As a result, it is increasingly used for packaging up-market or trendy items such as watches, perfumes, and mobile telephone cards.

The "shaped can" technology permits the production of cans in a diversity of shapes.

Canned Food Safest

Food canning is a long established and well-understood technique, which has served consumers well for nearly 200 years. It produces shelf stable products that can be stored at ambient temperatures.

Essentially, food, which has been processed, is sealed in a tin-coated steel can. The can is then subjected to heat to raise the temperature to a predetermined level for a definite period to kill the food spoilage organisms, which if present in the food, cause food poisoning. Since steel exhibits best sealing properties, the food stays sealed inside the can, foreign contamination is prevented and the food remains healthier and tastier for a long time. A study made by the University of Illinois, USA confirms that the canned foods are excellent alternatives to fresh & frozen food as they retain all the nutrition values found in the fresh food.

Corrosion of steel based cans is an oxidation-reduction reaction and can occur as a result of cans being in contact with dissimilar metals or being stored in a humid environment. Hence cans are coated/enamelled/lacquered both internally or externally to prevent corrosion and,

To prevent interaction of the can with the food product

To aid in handling and decorating the can

Can coatings/enamels/lacquers should have the following properties

Impart no odour or flavour to the food

Must be acceptable for contact with foods - i.e. non-toxic

Must protect the can and contents during the required shelf-life

Must not flake of the plate during can manufacture or storage

Must be of nominal cost, easy to apply and quickly cured.

Must withstand all temperatures encountered during processing and storage.

Quality Control tests on cans

Can seal integrity is the most commonly carried out quality control test on cans.

Hard Facts

Tin cans provide longest shelf life - a minimum of 2 years!! No other packaging medium offers such a long shelf life for packed food - making it the most dependable packaging medium to keep the food in prime condition. Steel base of tinplate makes it the most tolerant and robust packaging medium with power to resist insects, germs, bacteria and above all - the ultra-violet light, which helps the food to retain its aroma and flavour and also to withstand the poorest handling and transportation conditions. The excellent surface quality and finish of tinplate offers best print-ability options compared to all other packaging medium - giving it a premium look on the shelf.The range of coatings and surface finish available in tinplate makes it ideal for a wide range of applications right from food packaging to dry cell jackets, crowns closures and even toys.

Eco-friendliness

Tin cans are 100% degradable, Eco-friendly packs, which do not cause any environmental imbalance. Steel packaging is totally recyclable - it can be recycled for infinite number of times without ever changing the properties of steel. Thanks to its magnetic properties - which makes it the easiest type of material to be collected and sorted for recycling.Tinplate packaging is the best recyclable packaging material - perfectly suited for an age in which commercial success can depend on sound environmental credentials.

Great Savings

More than 50% of worldwide steel production is made up of steel scrap. The rates of recycling for steel packaging are high and growing steadily. There is a huge saving in recycling the steel scrap.Every ton of scrapped tin cans saves approximately

1.5 ton of Iron ore

665 kgs of Coal

191 kgs of Limestone

And above all, saves 70% of power consumed in steel making.

To summarize

Advantages of tinplate cans in food packaging

Provide excellent barrier properties (gases, water vapour, light, odours)

Can be used in on-line filling processes

Cheap to produce in large quantities

Good mechanical strength

Can be heat-treated, suitable for sterile products, can be hermetically sealed

Tinplate can be easily recycled

Not suitable for use in the microwave oven

here

for

price

We will contact with you within 8 hours