- Oil Pipeline

- Water Pipeline

- Gas Pipeline

- Boat and Mooring Accessories

- Metal for Decoration

- Transformer Components

- Heat Exchanger Pipe

- Air Conditioning Spare Parts & Accessories

- Boiler

- Kitchen and Bathroom Appliance

- Metal for Household Appliance

- Solar Power Appliance

- Elevator

- Roofing and Ceiling

- Cable

- Tank

- Packaging

- Machinery and Equipment Spare Parts & Accessories

- Mold

- Automobile Parts

- Rail and Crane Rail

- Hardware Fitting

- Abrasive

- Road Construction Equipment

- Electronic Components

- Construction and Decoration Materials

- Doors and Windows

- Refrigerators

冶金复合双(多)金属无缝管

Bonding strength more than: 300 Mpa

Metallurgical bonding bimetal composite pipe of Shanghai Metal Corporation is the combination of primary industry material and high technology of metallurgical process, through the typical hot extrusion or hot extrusion and cold forming process, metallurgical bonding interface of multiple material and base material can be achieved, so as to obtain high quality composite pipe. At the same time, as the pipe forming technology is extrusion process and the extrusion process is a three compressive stress state, so the performance difference of pipe in vertical and horizontal is small and the quality is superior. It is widely used in high temperature and high pressure, strong corrosion, high wear and tear and other harsh working environment such as petroleum, chemical, refinery, gas, boiler, power plant, mining machinery, ship, vehicles and so on.

Superior Performance:

1.Inside and outside layer is metallurgical bonding, base and multiple layers have enough bonding strength which is more than 300Mpa in normal conditions.

2.Composite material can enhance strength and toughness of the corresponding base material, achieving mechanical properties complementary.

3.Different brand of base material can obtain different mechanical properties for composite pipe.

4.Different performance of composite materials can obtain good resistance to high temperature and high temperature and high pressure, to bad environment corrosion and wear resistance ability, extending the service life of steel pipe.

5.Such as the chloride ion stress corrosion cracking, crack growth will meet base material and stop, good corrosion resistance of interface alloy can still guarantee the safety of pipe.

6.Good ductility and larger interfacial bonding strength which can realize reprocessing such as any turning, cutting, tapping, heating bending, pushing tee system, reducing, etc.

7.The internal and external layer metal has enabled the real metallurgical bonded, both inside and outside layer metal formed a solid concrete so welding of Bi-metal pipe is the same as single metal pipe.

Composite pipe is a kind of engineering pipeline that develops rapidly nearly ten years abroad, it has wide varieties and functions. At present, domestic and overseas bimetal composite pipe is mostly formed by the mechanical method (explosion forming, tube hydro forming, drawing, rolling, etc. ), both inside and outside layer metal is simple mechanical bonding, the combining boundary exists macroscopic clearance, so it is hard to meet the high-end user’s requirements.

Metallurgical bonding bimetal composite pipe of Shanghai Metal Corporation is the combination of primary industry material and high technology of metallurgical process, through the typical hot extrusion or hot extrusion and cold forming process, metallurgical bonding interface of multiple material and base material can be achieved, so as to obtain high quality composite pipe. At the same time, as the pipe forming technology is extrusion process and the extrusion process is a three compressive stress state, so the performance difference of pipe in vertical and horizontal is small and the quality is superior. It is widely used in high temperature and high pressure, strong corrosion, high wear and tear and other harsh working environment such as petroleum, chemical, refinery, gas, boiler, power plant, mining machinery, ship, vehicles and so on.

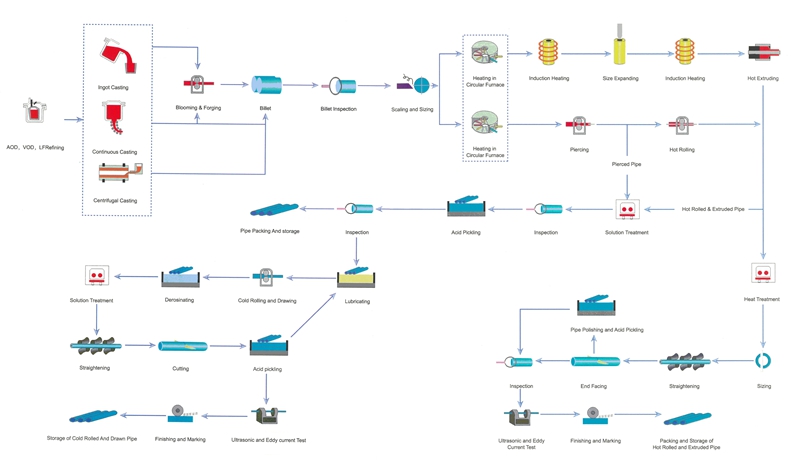

Production Process:

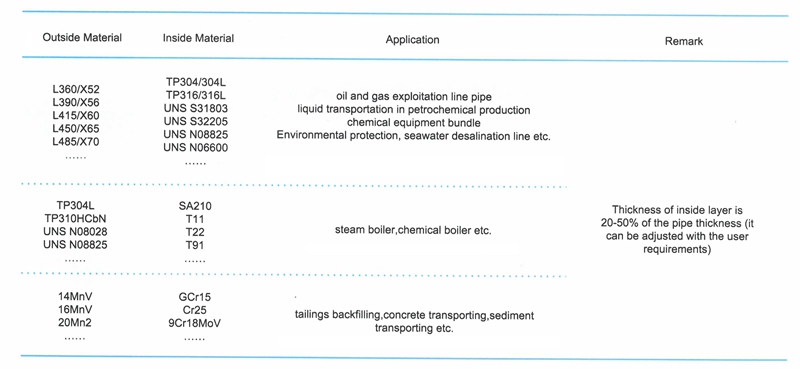

Product and application

Application:

Oil and gas exploitation

Flow line

Gathering and transportation line

Fluid pipeline

Heat exchanger

Condenser

Superheater

Testing Data:

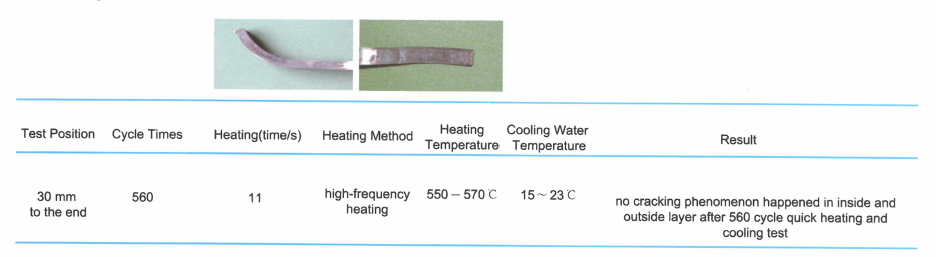

1.Fatigue test-transection

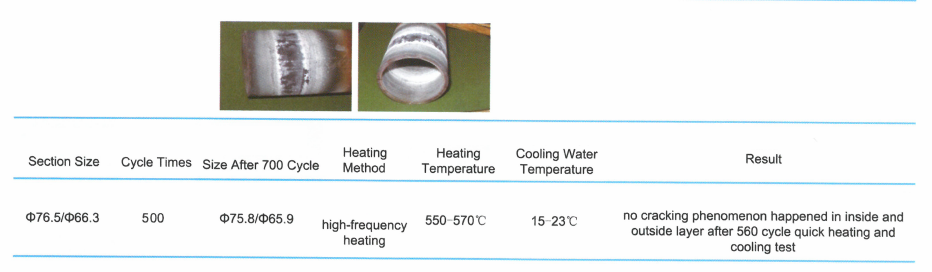

2.Fatigue test-tubulation

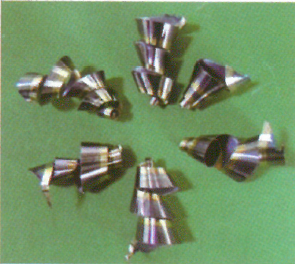

3.Turning

Through the steel cutting, it can be seen that two layer metal still remain solid concrete without any separation and cracking phenomenon, just like the processing of single metal, while the mechanical composite steel pipe can’t be like this.

here

for

price

We will contact with you within 8 hours